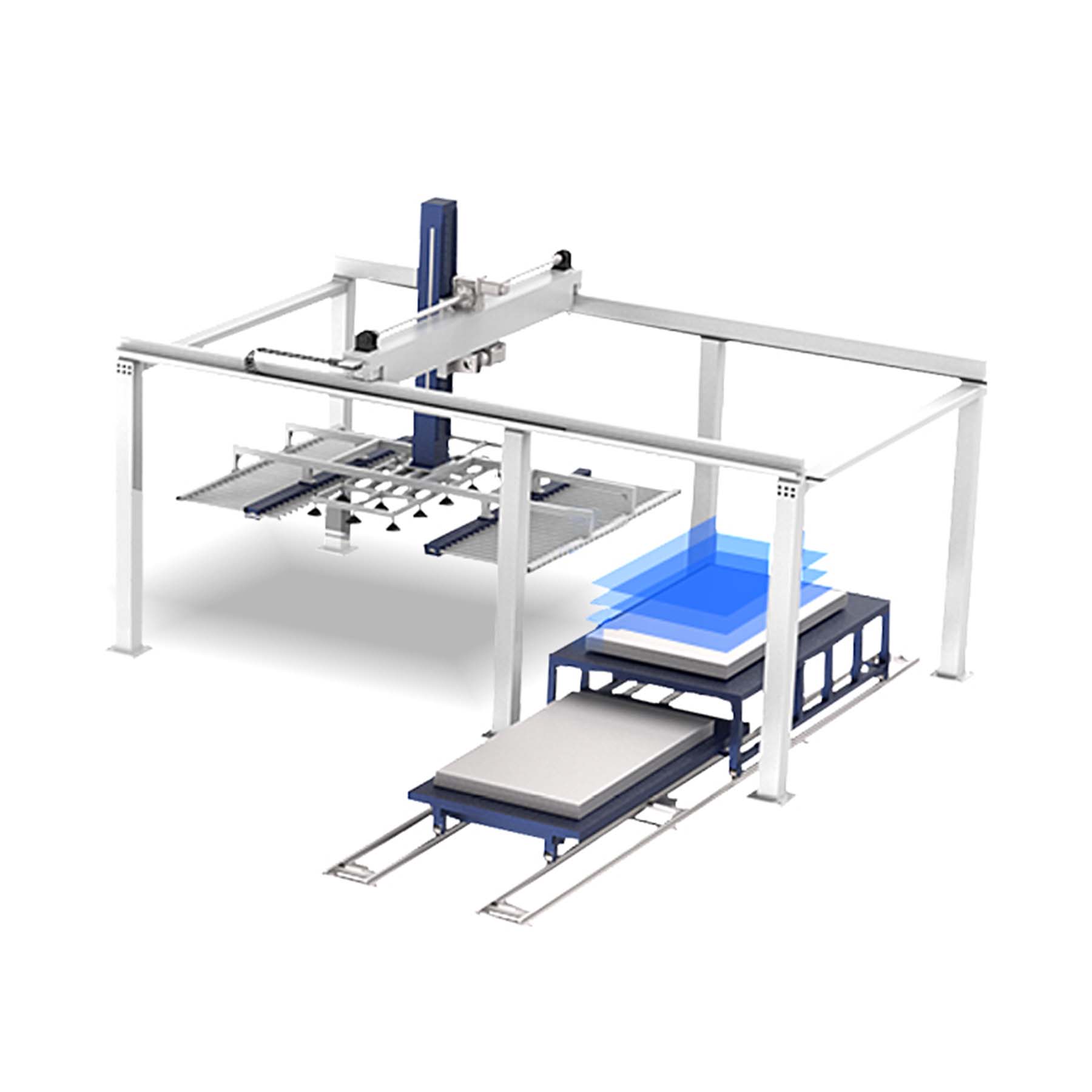

Sheet Metal Production Line

Description:

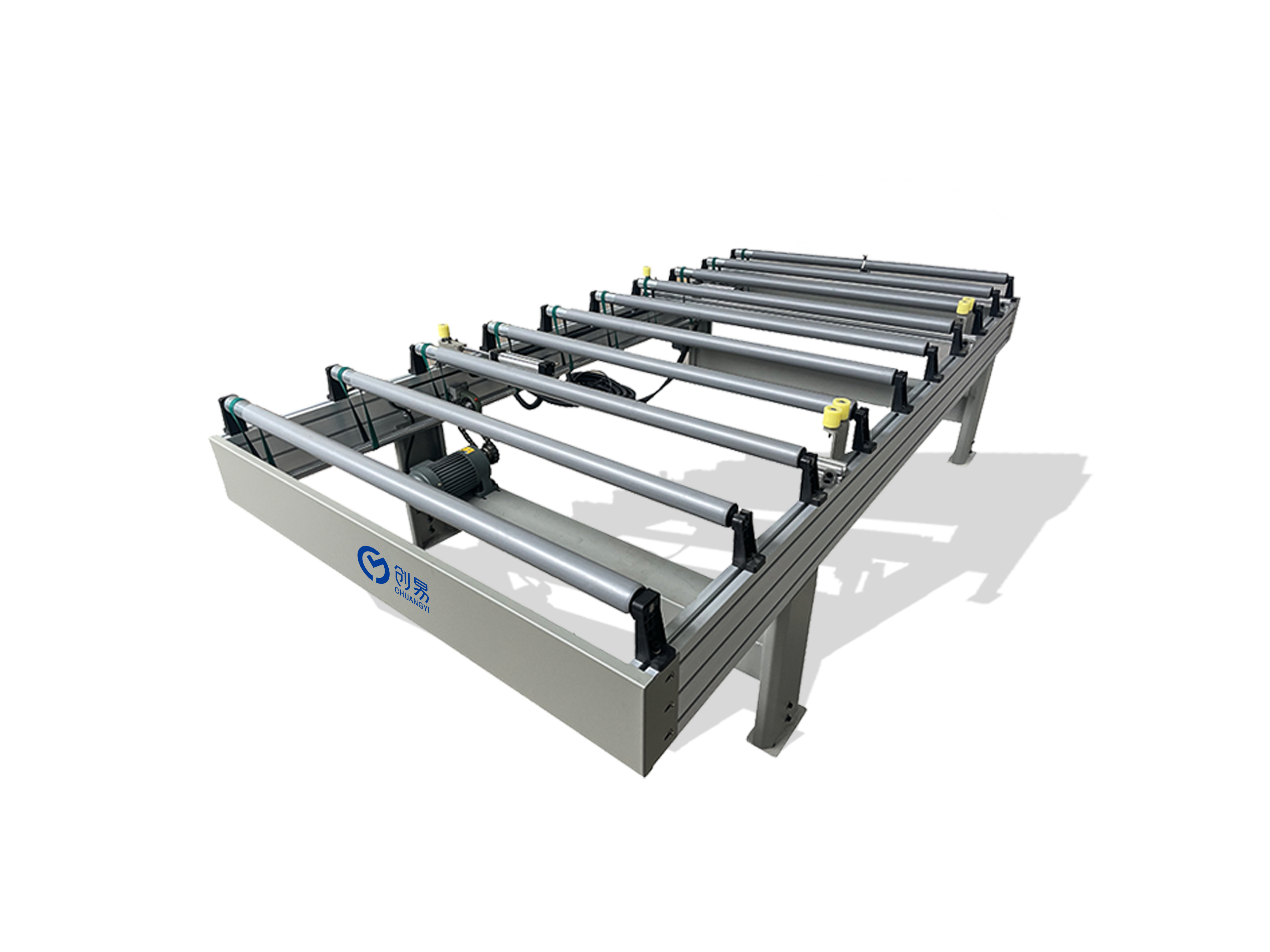

1. Large Load Capacity;

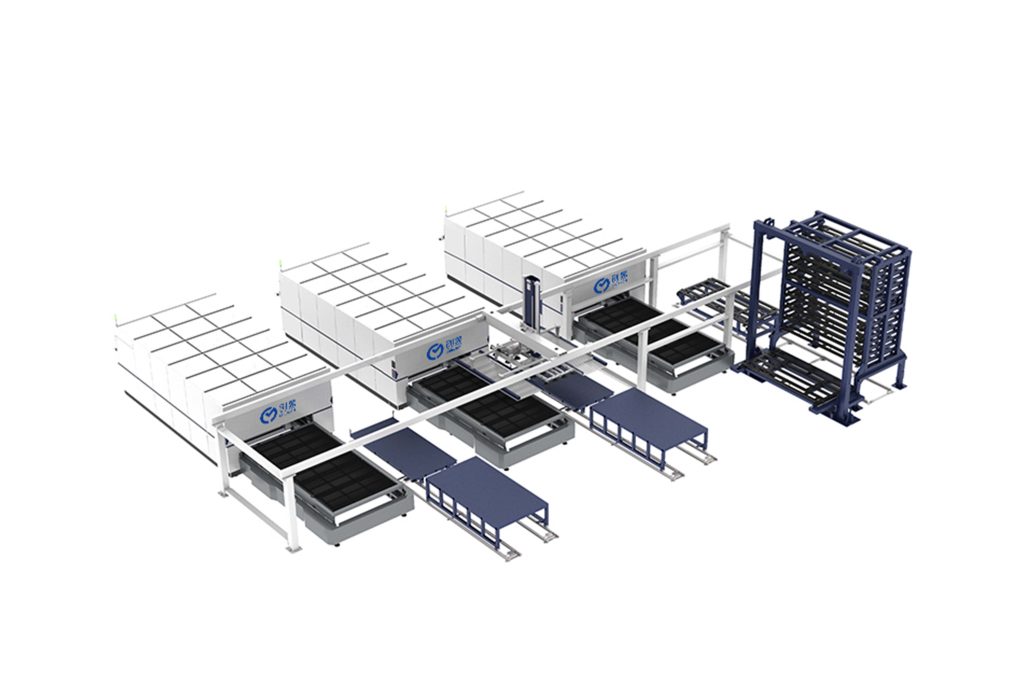

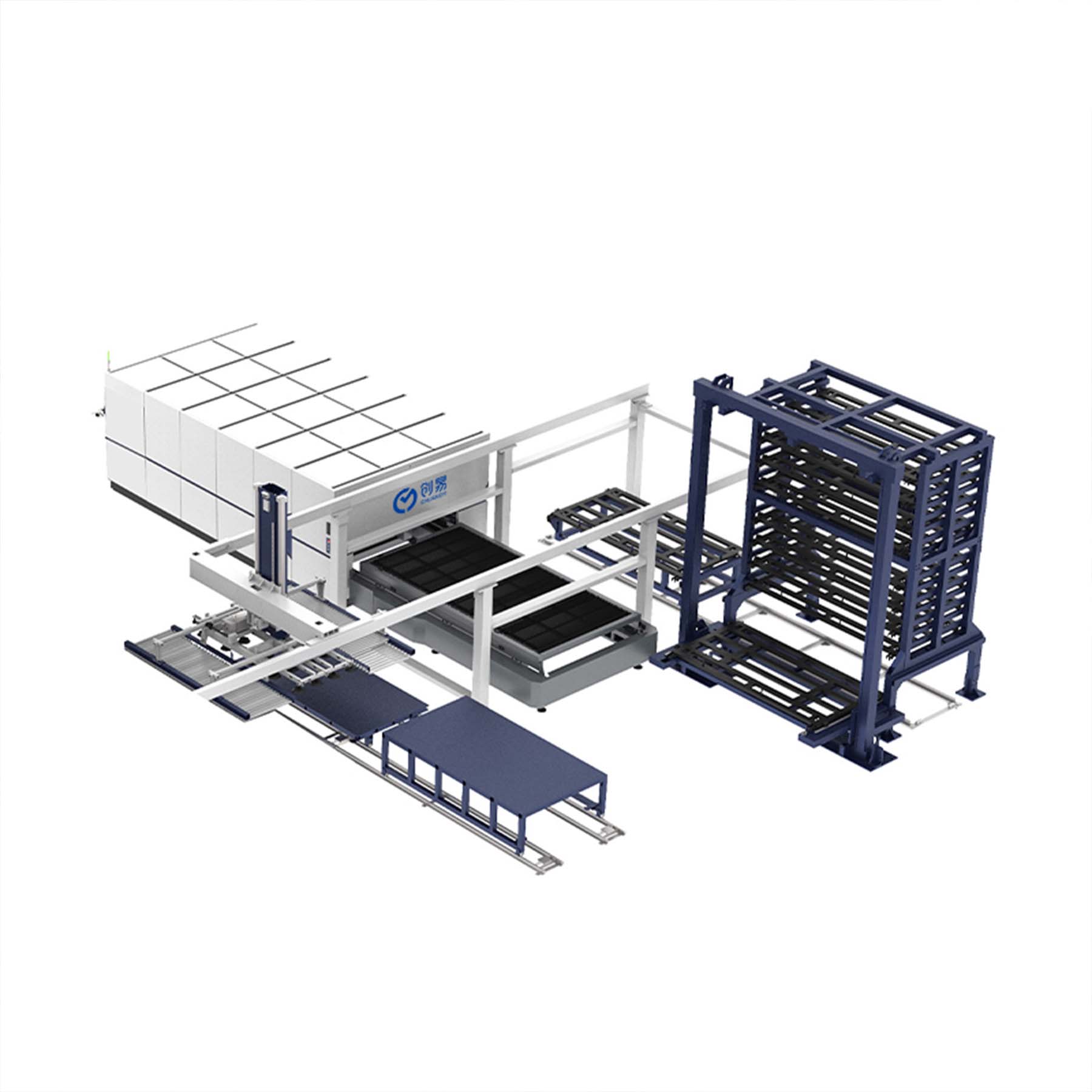

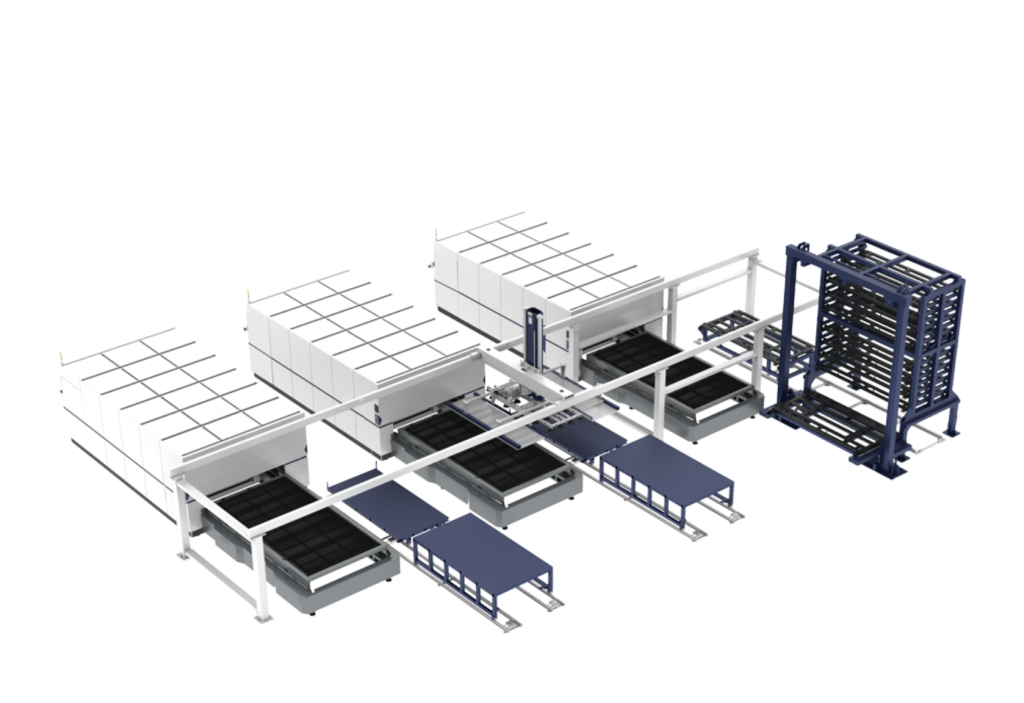

2. It Can Be Combined With The Plate Laser Cutting Machine And TheTower Silo To Realize Automatic Storage, Loading, And Unloading OfMetal Plates;

3. The Standard Parallel Cylinder Wears Less On The Transmission Parts and Increases The Service Life Of The Equipment;

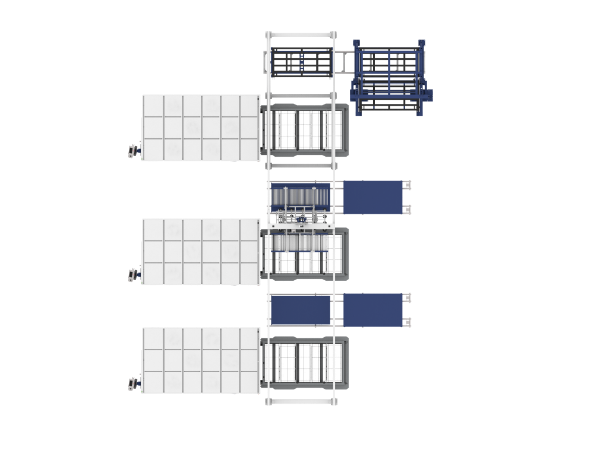

4. It Is More Flexible To Match With Equipment, Both Vertically AndHorizontally;

5. Fast Speed And High Efficiency;

6. Realize Small Parts Cutting;

7. Optional Electric Vehicles Can Realize 24-Hour Smart Factory;

8. Enhance Brand image;

9. Bus System, Bus Absolute Value Motor, Strong Anti-InterferenceAbility, No Need To Return To The Origin When Starting Up, FasterTransmission Speed, Standard Teach Pendant, Saving OfflineProgramming Time; Remote Control Can Be Realized.

Technical Parameter

| Device name | Quantity |

| Warehouse | 1Group |

| Loading and unloading Robot | 1set |

| Electric cart | ≦3tower |

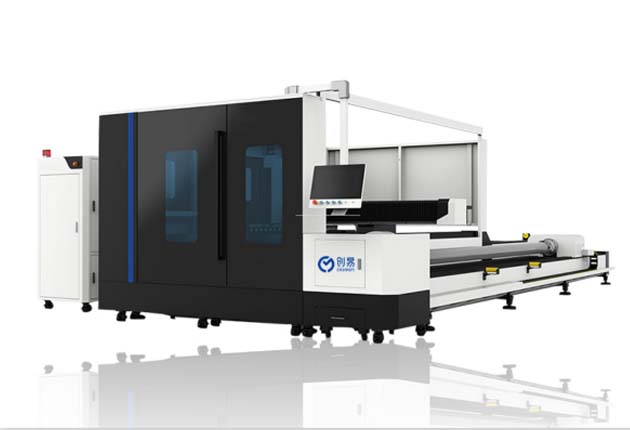

| Laser cutting machine | ≦3tower |

| Central control system | 1set |

Product Details

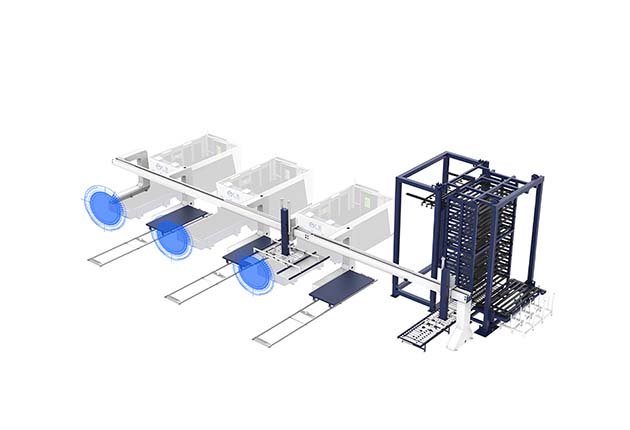

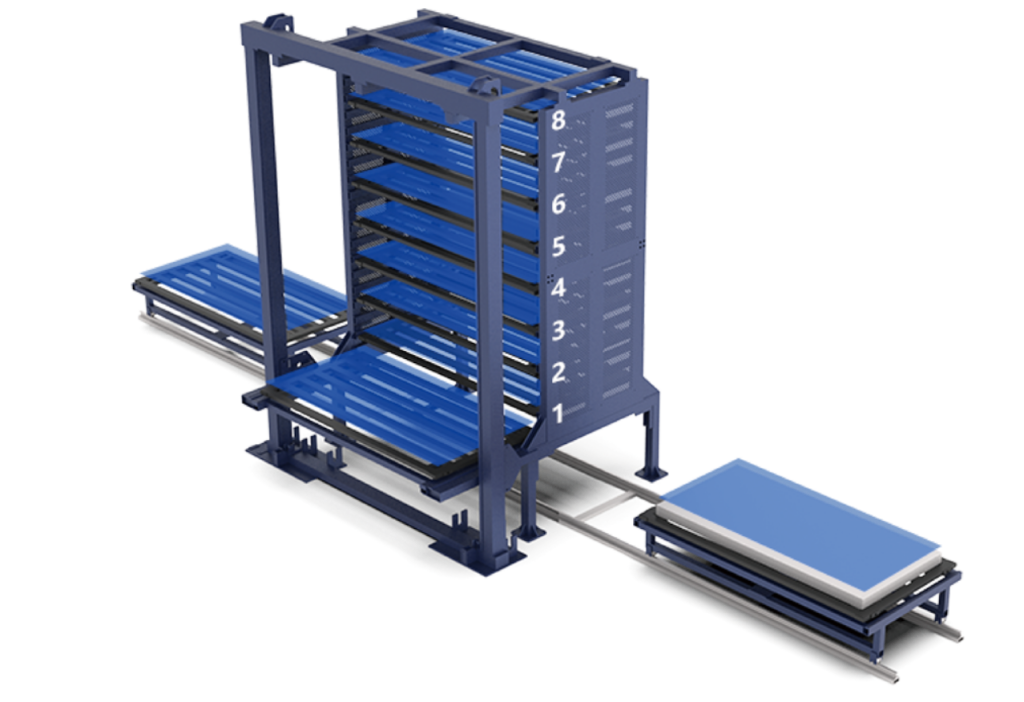

Scientific and compact plate storage solution

Systematic bulk storage of plates for scientific deployment and production. The tower-type three-dimensional material warehouse makes full use of the three-dimensional space and provides convenience for production.

Unattended fully automatic processing

Modular expansion, support for one-to-many jobs

A single set of loading and unloading systems can take care of the automatic loading and unloading operations of multiple cutting equipment at the same time, freeing up the workshop space while saving energy and reducing consumption.

Application Area

Related Products

Pipe Semi-automatic...

The automatic loading and unloading of the laser pipe cutting machine ...

LC Series Gantry Robot

Chuangyi LC series gantry robot, single-beam truss-type feeding device ...

Colomn Robot

The column robot (automatic loading and unloading robot) cooperates with ...

Four-axis Robot

Four-axis column robot is a special operation robot developed according to sheet ...

LH Series Gantry Robot

Chuangyi LH series gantry robot, a double-beam truss-type feeding device, improves ...